Camshafts play a crucial role in the operation of an internal combustion engine. They control the timing and duration of the engine's valve opening and closing events, which ultimately determines the intake of air and fuel and the expulsion of exhaust gases. Let's explore how camshafts work in a vehicle:

- Location: The camshaft is typically located in the engine block, above the crankshaft. It runs parallel to the crankshaft and is driven by a timing belt or chain, which connects it to the crankshaft.

- Camshaft Design: A camshaft consists of a cylindrical shaft with a series of specially shaped lobes or cams spaced along its length. The number and arrangement of these cams depend on the engine design and the number of valves per cylinder.

- Valve Actuation: Each cam lobe corresponds to a specific valve, either an intake or an exhaust valve. As the camshaft rotates, the lobes push against various components (such as rocker arms, pushrods, or directly acting on the valves) to open and close the valves at precise moments.

- Valve Timing: The shape and profile of the cam lobes determine the valve timing. The lobes are designed to provide the correct timing for intake and exhaust events based on the engine's requirements. This timing ensures efficient combustion and optimal power delivery.

- Valve Lift: The shape of the cam lobes also determines the amount of lift, which refers to how far the valves open. Higher lift allows more air and fuel into the cylinders during intake and better expulsion of exhaust gases during exhaust, enhancing engine performance.

- Camshaft Operation: The rotation of the crankshaft, driven by the pistons, causes the camshaft to rotate at half the speed. This is because the camshaft typically has half as many lobes as there are cylinders in the engine. For example, a four-cylinder engine usually has a two-lobed camshaft.

- Timing Control: In modern engines, the camshaft timing can be variable. Variable valve timing (VVT) systems use hydraulic actuators or phasers to adjust the position of the camshaft relative to the crankshaft. This enables optimization of valve timing for different engine speeds and loads, improving efficiency and performance.

Overall, camshafts control the precise timing and lift of the intake and exhaust valves in an internal combustion engine. By managing these valve events, camshafts contribute to the engine's performance, fuel efficiency, and emissions characteristics.

So what makes the TI-VCT so special?!?!

The Mustang Coyote TI-VCT (Twin Independent Variable Camshaft Timing) is an engine variant produced by Ford Motor Company for the Mustang lineup. It is a modern, high-performance engine known for its power, efficiency, and advanced camshaft timing technology. Here are some key features and characteristics of the Mustang Coyote TI-VCT:

- Engine Configuration: The Coyote TI-VCT is a V8 engine, meaning it has eight cylinders arranged in a V-shaped configuration. It belongs to the Modular engine family produced by Ford.

- Displacement: The engine has a displacement of 5.0 liters, which refers to the combined volume swept by all eight pistons in the cylinders.

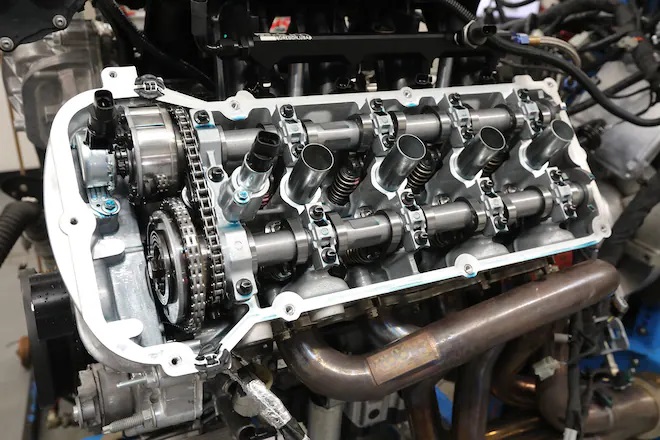

- Camshaft Design: The Coyote TI-VCT features dual overhead camshafts (DOHC), meaning there are two camshafts—one for the intake valves and one for the exhaust valves—located above each bank of cylinders. This design allows for more precise valve control and higher RPM capability compared to single overhead camshaft (SOHC) engines.

- Twin Independent Variable Camshaft Timing (TI-VCT): The TI-VCT system is a sophisticated technology that allows for independent control of the intake and exhaust camshafts. It enables the adjustment of camshaft timing on the fly, optimizing valve timing for different engine conditions.

- Benefits of TI-VCT: By adjusting the camshaft timing, the TI-VCT system improves engine efficiency, power delivery, and fuel economy. It helps maximize low-end torque, enhance high-end power, and optimize valve overlap for improved combustion efficiency.

- Power and Performance: The Coyote TI-VCT engine delivers impressive performance. While actual specifications may vary depending on the specific model year and variant, it generally produces over 400 horsepower and 400 lb-ft of torque. These figures are subject to updates and improvements made by Ford over time.

- Applications: The Coyote TI-VCT engine is primarily used in various Ford Mustang models. It has been featured in Mustang GT variants, providing a powerful and exhilarating driving experience.

Overall, the Mustang Coyote TI-VCT engine combines the traditional V8 power and sound with advanced camshaft timing technology. With its dual overhead camshafts and the Twin Independent Variable Camshaft Timing system, it offers a balance of performance, efficiency, and versatility for Mustang enthusiasts.

But, what is VTEC?!?! We may be a Mustang niche company, but many want to know!

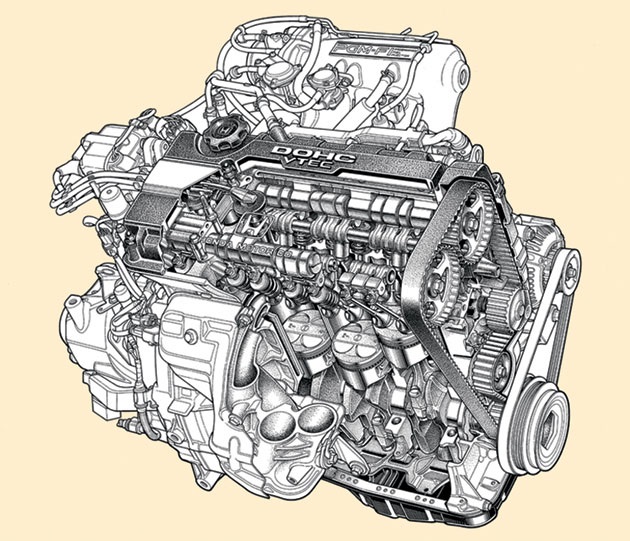

Honda's Variable Valve Timing and Lift Electronic Control (VTEC) is an advanced engine technology developed by Honda Motor Company. VTEC optimizes engine performance by varying the valve timing and lift of an engine's valves. Here's an explanation of how Honda VTEC works:

- Valve Operation: In an internal combustion engine, valves control the intake of air and fuel and the exhaust of combustion gases. Typically, engines have two camshaft profiles: one for low-speed efficiency and another for high-speed performance. VTEC allows the engine to switch between these profiles seamlessly.

- Three-Stage Operation: Honda VTEC operates in three stages: low-speed, high-speed, and transition.

- Low-Speed Stage: At low engine speeds, VTEC uses a low-lift, short-duration cam profile. This configuration optimizes fuel efficiency, improves idle stability, and enhances low-end torque.

- High-Speed Stage: As engine speed increases, VTEC engages the high-lift, long-duration cam profile. This profile promotes maximum airflow into the cylinders, resulting in improved high-end power and performance.

- Transition Stage: During the transition between low and high engine speeds, the VTEC system smoothly switches between the cam profiles to ensure a seamless and uninterrupted power delivery.

- Operation Mechanism: VTEC operates through the use of three main components:

- Camshaft Profiles: The engine has two sets of camshaft profiles—an economy profile for low-speed operation and a performance profile for high-speed operation. The camshaft profiles have different cam lobes that dictate valve lift and duration.

- Rocker Arms and Rocker Arm Shafts: The rocker arms are responsible for actuating the valves. In VTEC engines, there are two rocker arms per cylinder: one for the low-speed cam profile and one for the high-speed cam profile. These rocker arms are controlled by the rocker arm shafts, which are operated hydraulically.

- Oil Pressure Actuator: The VTEC system utilizes oil pressure to actuate the rocker arm shafts. At low speeds, the oil pressure actuator keeps the rocker arm shafts stationary, engaging only the low-speed rocker arms. As engine speed increases, the oil pressure actuator moves the rocker arm shafts, allowing the high-speed rocker arms to engage.

- Benefits of VTEC: Honda's VTEC technology provides several advantages:

- Increased Power: By optimizing valve lift and timing, VTEC engines offer improved high-end power and performance compared to traditional engines.

- Fuel Efficiency: At low speeds and during normal driving conditions, VTEC operates with the low-speed cam profile, which enhances fuel efficiency and provides better throttle response.

- Smooth Transition: The transition between the low and high-speed cam profiles is seamless and controlled, resulting in a smooth power delivery without any sudden surges or drops.

- Enhanced Engine Efficiency: VTEC allows for precise control of valve timing, which improves combustion efficiency, reduces emissions, and contributes to overall engine efficiency.

Honda VTEC has been utilized in various Honda models and has gained a reputation for delivering an optimal balance between performance and fuel efficiency, contributing to the brand's sporty and efficient driving experience.